Optimized processes for optimized products.

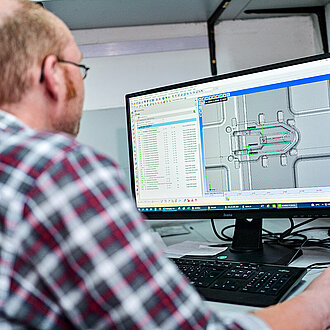

- 3D Modelling

- FEA (Finite Element Analysis) simulations

- Material Flow simulations

- CAD / CAM support

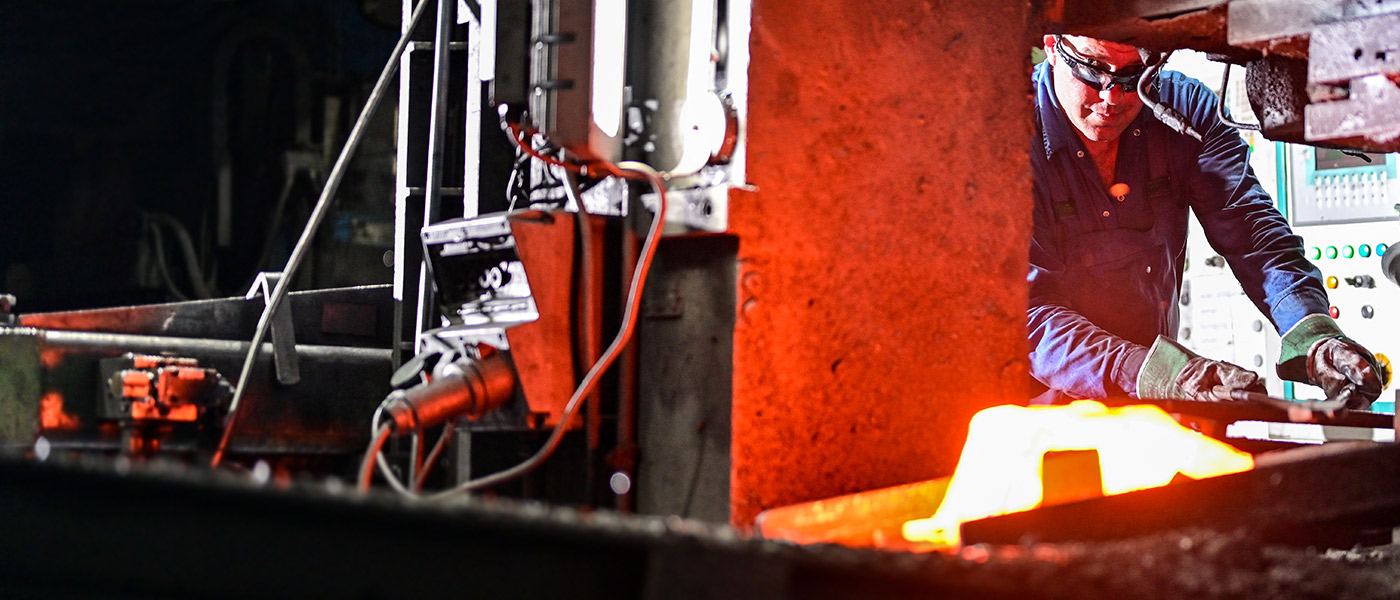

- Steel and titanium

- Fully automated forging press

- Press load from 1,600 to 3,150 ton

- Billet weights: 0.2 to 18 kilogram

- Calibration presses with 1,000 tons pressure force

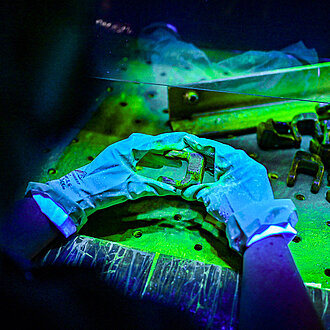

- Surface sandblasting systems

- Crack testing by magnetic powder method

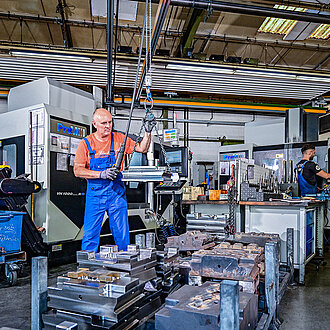

- Machining with two to four spindles

- Turning and milling center

- 3D measuring machine to optimize the assembly process

- Assembly of complete assemblies.